|

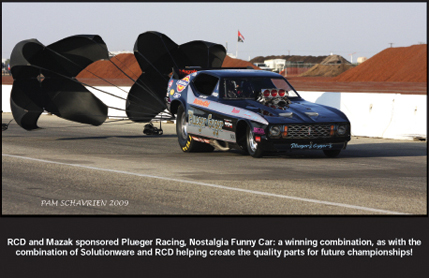

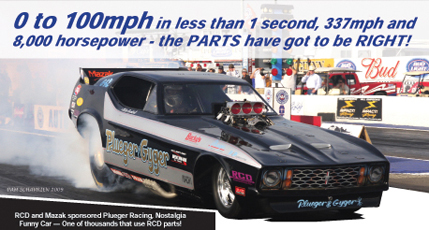

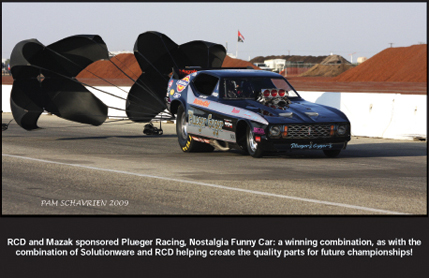

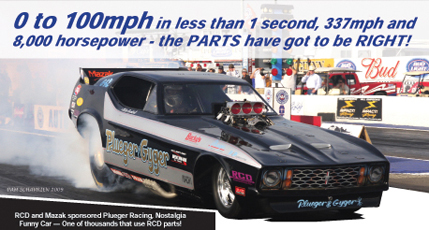

If you are involved in the sport of

drag-racing, tractor-pulling, high-performance boats or any sport where

horsepower reigns supreme, you are probably familiar with the racing and

performance parts made by RCD Engineering, Inc. located in the famous

gold-rush area of California.

Over the years, RCD has acquired a variety

of CNC machines to make the 2,500-3,000 different parts manufactured.

With such a variety of CNC machines and

controllers (mills, lathes, with various capabilities such as rotary-tables,

live-tooling, not to mention G-code and Mazatrol programming), RCD needed a

system that is not only versatile, but is able to meet the demands of the

various machines, so as to enable the shop to work smart. These machines

include a variety such as:

- Vertical Machining Centers: Enhsu Yasnac,

Excell Fanuc, Cincinatti Milacron, Mazak 510C Matrix.

- Horizontal Machining Center: Toyoda

FA450 Meldas control.

- Turning Centers: Mazak Quick-Turn with

F640T; Mazak Quick-Turn with Matrix Nexus and sub-spindle.

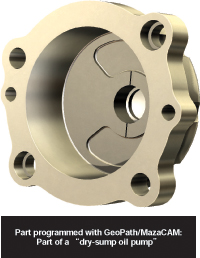

When RCD manufactures parts on their Mazak

and G-code CNC machines, they need a reliable system that quickly outputs

the right code. In this industry, parts quantities are short-run and there

is not a lot of parts to amortize the programming time, no matter how

complicated the part. To stay on top, RCD is continually looking for better

solutions. RCD invested in and tried other software after seeing some very

nice features in sales presentations, only to later find complications

actually running RCD’s CNC machines, so they again turned to SolutionWare’s

GeoPath/MazaCAM for results. When RCD manufactures parts on their Mazak

and G-code CNC machines, they need a reliable system that quickly outputs

the right code. In this industry, parts quantities are short-run and there

is not a lot of parts to amortize the programming time, no matter how

complicated the part. To stay on top, RCD is continually looking for better

solutions. RCD invested in and tried other software after seeing some very

nice features in sales presentations, only to later find complications

actually running RCD’s CNC machines, so they again turned to SolutionWare’s

GeoPath/MazaCAM for results.

Natchi Contreras, RCD’s General Manager,

says from experience "It’s not just software that makes your parts, a key is

the after-the-sale service and support, as you can buy all the software you

want and still get nowhere. Needs change and special situations come up and

with SolutionWare, we not only talked to tech-support, but when we told them

of a particular need we had, instead of being told ‘We’ll make a note of it’

with no action, we were surprised to get an actual software enhancement to

solve our issue within days! This support enables us to make parts and

deliver on-schedule and that counts in any industry if you want to keep

customers and make money. The thing that really surprised us is that

SolutionWare’s GeoPath/MazaCAM is less expensive and we get much better

service."

Natchi continues, "Sometimes people don’t see the value of annual service and updates, but quality service and software updates are valuable, because with the latest features you can create programs  faster and cut parts easier. With SolutionWare adding new features, this enables us to handle production challenges even better. SolutionWare continues to evolve their product and that gives us more tools and even smarter tools in the toolbox to get the job done right the first time!" faster and cut parts easier. With SolutionWare adding new features, this enables us to handle production challenges even better. SolutionWare continues to evolve their product and that gives us more tools and even smarter tools in the toolbox to get the job done right the first time!"

"Ease of use and ease of training are some

of the most important factors.", says Natchi. "With GeoPath/MazaCAM, if you

have your geometry, it is so quick to program with, a simple program can be

done in 15 minutes. With GeoPath/MazaCAM it takes 10-25% less time than

programming with the old method, at the control. Furthermore, when

programming at the control, there are various problems programming while the

machine is running, so usually the machine is not cutting parts. With

GeoPath/MazaCAM, we can program on the computer while the Mazak is cutting

parts."

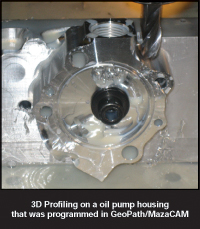

A further advantage is more efficient

machining practices. Take a part RCD machined that has six lobes. "Were

looking for something better in the lathe live-tooling milling aspect. With

the pattern of 6 lobes, we couldn’t program to rough and finish efficiently,

because generating the shape geometry is so time-consuming on the control.

Now with GeoPath/MazaCAM, we can place cuts where needed. As with all

live-tooling lathes, they don’t have the rigidity of a regular milling

machine making it important to make the cuts exactly as needed. We now have

a lot more freedom with the cuts, because it is so easy to pick geometry and

program." A further advantage is more efficient

machining practices. Take a part RCD machined that has six lobes. "Were

looking for something better in the lathe live-tooling milling aspect. With

the pattern of 6 lobes, we couldn’t program to rough and finish efficiently,

because generating the shape geometry is so time-consuming on the control.

Now with GeoPath/MazaCAM, we can place cuts where needed. As with all

live-tooling lathes, they don’t have the rigidity of a regular milling

machine making it important to make the cuts exactly as needed. We now have

a lot more freedom with the cuts, because it is so easy to pick geometry and

program."

"In today’s competitive world, you need

every edge you can get to stay on top and make money. With the latest

software updates, we are now making parts that we couldn’t with other

software and have made our money back from the cost of the service-agreement

in just a few weeks."

|

When RCD manufactures parts on their Mazak

and G-code CNC machines, they need a reliable system that quickly outputs

the right code. In this industry, parts quantities are short-run and there

is not a lot of parts to amortize the programming time, no matter how

complicated the part. To stay on top, RCD is continually looking for better

solutions. RCD invested in and tried other software after seeing some very

nice features in sales presentations, only to later find complications

actually running RCD’s CNC machines, so they again turned to SolutionWare’s

GeoPath/MazaCAM for results.

When RCD manufactures parts on their Mazak

and G-code CNC machines, they need a reliable system that quickly outputs

the right code. In this industry, parts quantities are short-run and there

is not a lot of parts to amortize the programming time, no matter how

complicated the part. To stay on top, RCD is continually looking for better

solutions. RCD invested in and tried other software after seeing some very

nice features in sales presentations, only to later find complications

actually running RCD’s CNC machines, so they again turned to SolutionWare’s

GeoPath/MazaCAM for results. faster and cut parts easier. With SolutionWare adding new features, this enables us to handle production challenges even better. SolutionWare continues to evolve their product and that gives us more tools and even smarter tools in the toolbox to get the job done right the first time!"

faster and cut parts easier. With SolutionWare adding new features, this enables us to handle production challenges even better. SolutionWare continues to evolve their product and that gives us more tools and even smarter tools in the toolbox to get the job done right the first time!"  A further advantage is more efficient

machining practices. Take a part RCD machined that has six lobes. "Were

looking for something better in the lathe live-tooling milling aspect. With

the pattern of 6 lobes, we couldn’t program to rough and finish efficiently,

because generating the shape geometry is so time-consuming on the control.

Now with GeoPath/MazaCAM, we can place cuts where needed. As with all

live-tooling lathes, they don’t have the rigidity of a regular milling

machine making it important to make the cuts exactly as needed. We now have

a lot more freedom with the cuts, because it is so easy to pick geometry and

program."

A further advantage is more efficient

machining practices. Take a part RCD machined that has six lobes. "Were

looking for something better in the lathe live-tooling milling aspect. With

the pattern of 6 lobes, we couldn’t program to rough and finish efficiently,

because generating the shape geometry is so time-consuming on the control.

Now with GeoPath/MazaCAM, we can place cuts where needed. As with all

live-tooling lathes, they don’t have the rigidity of a regular milling

machine making it important to make the cuts exactly as needed. We now have

a lot more freedom with the cuts, because it is so easy to pick geometry and

program."