|

Communication / Transferring Mazatrol

Programs to and from the Mazak CNC

Let’s talk about how to make sending and receiving programs to your CNCs as

reliable and efficient as possible. Many shops have been attempting to work out

this problem; some have succeeded and others know that things could be done

better.

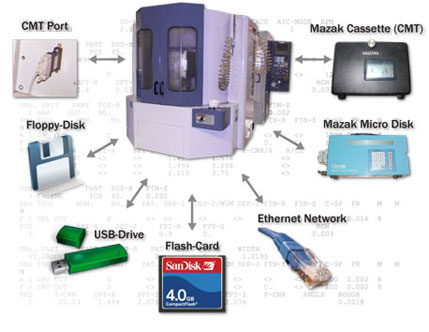

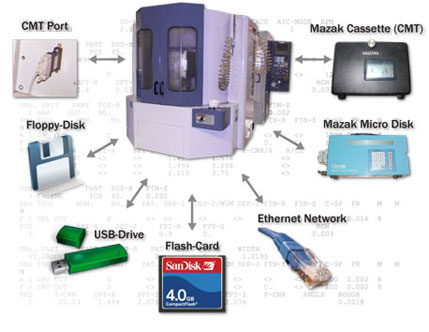

The Mazak CNC (with Mazatrol programs) has a number of methods (varying over the

Mazak generations) of communicating / transferring Mazatrol programs to and from

the Mazak CNC.

First, let’s start with the basics. What is CMT?

The first Mazatrol control, the T1, saved programs to a Cassette Magnetic Tape,

and hence the abbreviation “CMT”. This used a serial-port (“RS232”) to

communicate between the Mazak CNC and the Cassette (CMT) unit.

This “CMT-I/O” uses the same 25-pin connector found on the earlier IBM-PC

compatible computer, and later the IBM-PC changed it to a 9-pin configuration

(although the Mazak remained at the standard 25-pin configuration, it is a

simple wiring adapter difference). Note that while the RS232 connector is

industry-standard, the “CMT-I/O” communications “language” that the Mazak

communicates with over the cable is not the industry standard, and requires

special software to communicate (such as Mazak Corp’s “MDT” software or

SolutionWare Corp’s MazaCAM software).

Ethernet Network connections became available starting with the Fusion

generation (as an inexpensive option) and continued on later generations. Files

can now be transferred via the Network to a computer acting as a file server.

This type of communications does not require the plugging and

unplugging of hardware, thus less wear and tear on your machine and less chance

of getting chips on your connectors.

Mazak CNCs, depending of the generation, have other methods of transferring

programs with various types of hardware. Fusions and Fusion-Pro controls have a

Windows-compatible floppy-disk and may have a “Compact-Flash”-Card where

available. The Matrix control replaced the floppy-disk with the more reliable

USB drive.

A Mazatrol program can not contain a virus, so the Mazak programs and data-files

themselves are perfectly safe to transfer. However, the method used to transfer

those requires some kind of connection with another device: USB-drive,

Flash-card, Floppy-drive, RS232 serial-port, or Network connection.

Each of these methods has plusses and minuses:

- "CMT-I/O” RS232: has the potential of

transmission errors when transferring Mazatrol programs. Plusses are it is

standard on all controls prior to the Matrix, and there is no chance of

transferring a virus via a standard RS232 data transfer.

- Network connection:

(available on Fusion and later) if done correctly this can

be virtually virus-free and is the best method. On the other hand, if done

incorrectly or proper policies are not enforced, this can be the most common

method of virus-infection.

- Wireless Ethernet: With the Ethernet interface,

one can use various wireless Ethernet units available. The minus is sometimes

the signal is unreliable. The plusses are no electrical connection means

protection from electrical surges and lightning. And no need to run wires all

the distance across the shop.

- USB-drive: (available on Matrix) is the simplest

method to transfer programs as it requires virtually no configuration. But can

transfer a virus (since Windows automatically runs certain files if it finds

them on the drive when it is inserted, and these can be virus-infected). It is

vital that you make sure any USB-drive used for program transfer is verified

virus-free regularly.

- Compact-Flash "Card": is pretty much the same

plus/minus as USB-drive.

- Floppy-disk: Although if used properly, this

method can be kept virus-free, data retention is not completely reliable on a

floppy-disk.

- Wireless RS232: While this can eliminate wiring

and protect from electrical surges and lightning, some units do not work well

with Mazaks, and sometimes the signal is unreliable. Set-up is more

complicated then simply running a wire.

For further information on these topics (or any Mazatrol or CNC programming

topic), see our website CNCproductivity.com

or contact us at 408-249-1529 or 888-322-3226 toll-free in the USA.

If you would like to make comments on this Machining in

the ZONE go to

TheMazatrolAdvantage.com, and join the forum.

Click here for a more detailed history on Mazak Communications

|